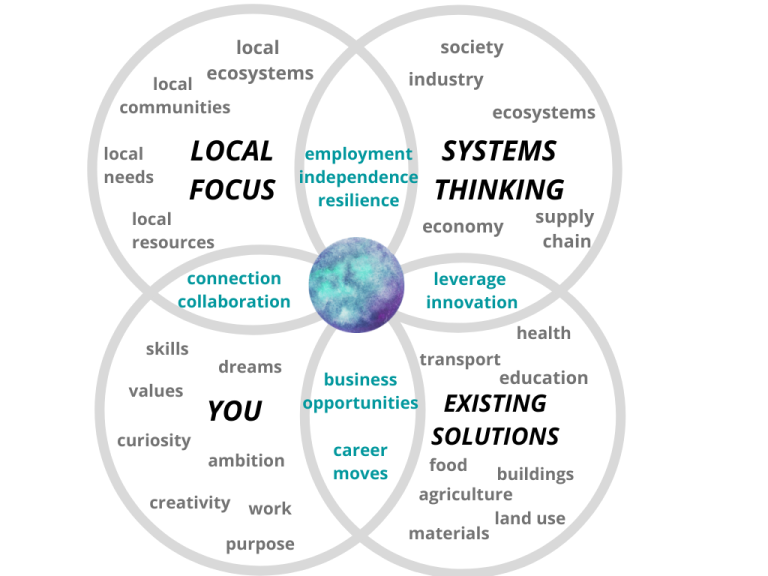

4 places to seek sustainability advantage

In an earlier post, I talked about the 10 key assumptions that blind many businesses to sustainability opportunity. Once you understand them, it’s time to explore your business.

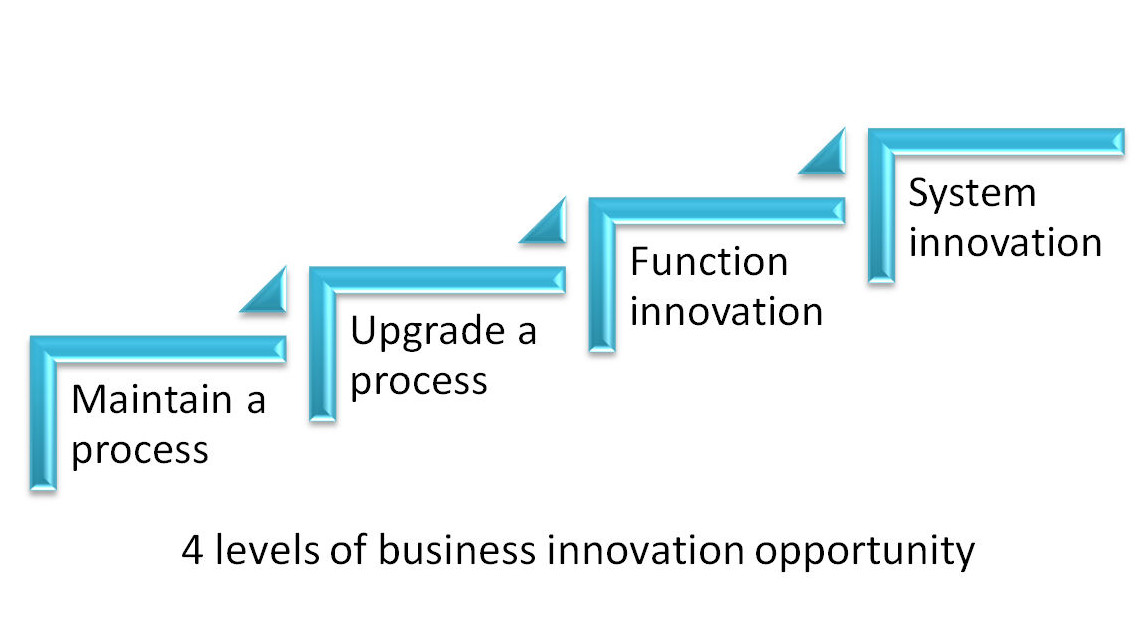

There are also four key levels of business activities that you can use to explore for opportunities “hiding in plain sight”.

- Your product/process maintenance and improvement

- Your product/process upgrades

- Function improvements

- Systems innovation

Choosing and actioning your best opportunities may require “decision-making in the round” – but it can be exciting, challenging and exhilarating, too.

Technology moves fast – are you missing out?

Back in 2010 The Blue Economy report listed Vortex Processing Technology as a powerful platform for delivering big water and energy efficiency savings. Today – just 8 years later – it’s in commercial use across the EU and spreading in to North America.

Supporting technologies including analytics and industrial 3D printing accelerated its commercialisation.

What ever industry you’re in, there will be emerging technologies could you leverage to gain a local first mover advantage – if you’re watching for them.

As concerns about global warming grow and innovative corporations increasingly engage in solutions commercialisation, there is a growing range of smart solutions joining the smart watch on the move from “fantasy” to “practical product”.

1. Check your day-to-day maintenance and improvement

It may be your plant and equipment maintenance process. It could be responding to customer concerns or employee suggestions. It’s surprisingly easy to get habituated to something that’s “OK”, or to miss opportunities for small improvements that have big downstream impacts.

When did you last clean the refrigeration coils on your cooling equipment and refrigerators? (Especially in a dusty environment). How recently did you have them checked for refrigerant gas integrity? (Many refrigerant gases are thousands of times more greenhouse-intensive than CO2.)

Would it be worth installing separate metering or a smart controller on your water supply, to find out the specific usage of different parts of your operation?

What practical, “boring” maintenance could make a difference to your sustainability footprint?

2. When you actively review a product or process to update it

There’s a wealth of new technology coming on stream every few months – and it’s not just in communications technology. For more than 30 years, the world’s innovators and early adopters have been exploring for better solutions, and the information processing revolution is accelerating their efforts.

So every time you review your equipment – any and all of your equipment – you have an opportunity to find a smarter, more innovative solution. There will likely be something new that will help you save energy, water and money.

A Queensland farmer facing massive power bills for his irrigation equipment was able to go off-grid when he redesigned the equipment layouts. He had originally had one big pump driving all his equipment. Reviewing the installation, he switched to smaller pumps. More, smaller pumps driving individual modules could operate on solar+battery, taking him off-grid.

3. Functional improvements

Looking at how a whole business function is performed, rather than a single process can uncover significant opportunities.

Carpet manufacturer Interface reviewed how they made carpet tiles in a particular factory several years ago. The process as designed was to tuft plain tiles, then print designs on to them. In their quest to improve their sustainability, one engineer noticed that the machine could be programmed to tuft designs using different coloured yarns.

Changing their process from tuft-then-print to multi-coloured tufting removed an expensive, water-consuming, chemical-intensive process – and a whole lot of cost – without any effective change to the end product.

4. System improvement

Serial Melbourne entrepreneur Steve Morriss has started a new business turning food waste into fertilizer. He’s combining 3 existing technologies to create a whole new business. Food waste is a massive global warming challenge – in terms of both production and disposal.

Food waste can be processed using worm farms – but worm farms at scale require country acres remote from the waste. By combining vermiculture with food waste dehydration and anerobic digestion, Circular Food is turning food waste into fertilizer.

A team of scientists working in outback South Australia has reinvented tomato growing. They’re using sun and seawater to grow soil-free, pesticide-free tomatoes in an innovative greenhouse.

They pipe seawater to their 20-hectare site in arid Port Augusta. They then use a solar-thermal desalination plant to create enough fresh water to irrigate 180,000 tomato plants inside the greenhouse.

While the region’s extremes of temperature and low rainfall make conventional farming impractical, the greenhouse is a game-changer. Its seawater-soaked lining keeps the plants cool enough to stay healthy in summer, while solar heating keeps the greenhouse warm in winter. Seawater cleans and sterilises the air, and the plants grow in coconut husks instead of soil.

Decision making in the round

At every level of business operation – from maintenance to startup, there’s a whole new realm of sustainable business opportunity to be realised.

Today, “How much will it cost?” is an incomplete evaluation criteria. There is another, more strategic question to be asked.

When considering building a massive solar array for global corporate carpet manufacturer Interface, Dr Michael Bertolucci, head of interface Research, reflects on this new process:

“When I stepped back and looked at the .. proposal again, what it would MEAN as opposed to how it would PERFORM, I realised that … my classical approach to problem solving turned out to be the problem. What is the payback period for being a global leader? What is the return on investment for making a public commitment to a better world How will our main market … respond? Classical scientific analysis is not equipped to answer any of those questions… neither was classical accounting.”[i]

Industrial sustainability pioneer, Ray Anderson, CEO of Interface concluded: “Making decisions in the round, including marketing, sales, and the customer, always yields more accurate assessments, as well as better decisions.”[ii]

When you’re wondering where your opportunities lie, check all 4 levels of operation – and explore for what’s hiding behind old-style 20th century business assumptions.

Not sure how to spot YOUR opportunities? Then get in touch today…

_____________________________________________

[i] Ray Anderson and Robin White, “Confessions of a Radical Industrialist”, 2009, p. 98

[ii] Anderson and White, op. cit., p. 99-100